Controls used in the industrial sector and in the railway and aeronautical sectors.

IRIS

Internal Rotary Inspection System

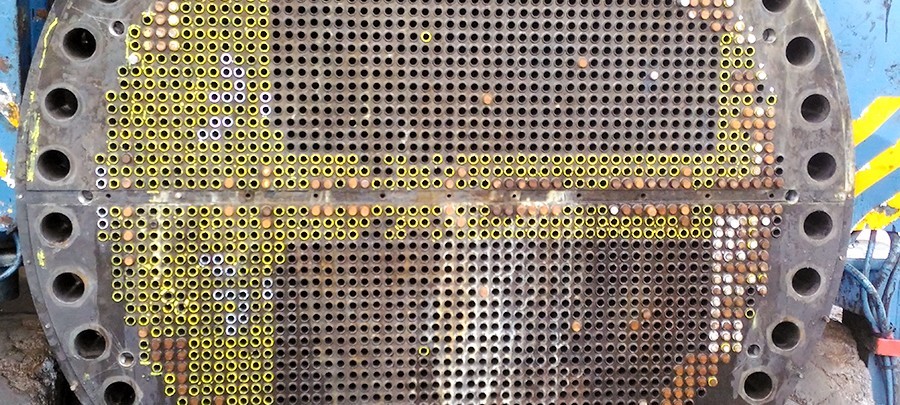

IRIS is used for ultrasonic checks on a wide spectrum of materials including ferrous, non-ferrous, and non-metallic pipes, such as: Shell-and-tube heat exchangers, condensers, refrigerants, Aircoolers, and tubular reactors.

The technique detects and evaluates reductions in the walls due to corrosion, erosion, wear and pitting.

IRIS technology uses ultrasounds propagated by a probe with a rotating head which is made to slide inside the tube to be analyzed.

The advantages of this method are:

- immediate value of residual thickness

- ability to record scans

- it does not require sample tubes, just knowing the material and the propagation speed of the ultrasound beam.

Eddy Current & RFT (Remote Field Test)

Eddy Current testing uses the variation of a magnetic field (primary field) through the passage of a coil to create a parasitic current in the piece to be controlled and create a second magnetic field (secondary field).

The detectable defects are:

all those that involve a deviation or variation of the magnetic field

variations in the thickness of the piece

superficial or sub-superficial defects inside the tube

through-holes

cracks

The materials that can be checked must have good electrical conductivity and NOT be ferromagnetic.

If the material is ferromagnetic, a similar control is performed but with a different probe called Remote Field Test (RFT).

ISPECO uses this technique mostly to control:

- Shell and tube heat exchangers, condensers, refrigerants

- Aircooler

- Tubular reactors

- control of welds, rivets etc. thanks to the aid of pen-shaped feeler probes.

The control probe must be of adequate size, therefore it is possible that it is tailored to each device. To carry out the calibration of the probe and to check, a sample tube on which artificial defects will be created will allow to estimate the defects found in the field.

ISPECO is equipped with instrumentation and a range of probes and sample pieces such as to cover most types of pipes and diameters.

EDDY CURRENT testing is not applied only to the industrial sector (tube bundles etc.), but also in the rail and aeronautical sectors.