Measurement of residual thicknesses and coatings and paints

The ultrasonic thickness gauge control is intended to measure the residual thickness on components, such as pipes and equipment, subject to degradation due to operation (corrosion, erosion, wear).

The check can be performed:

- on any material, knowing the speed of propagation of the ultrasound or having a sample piece of known size on which to perform the calibration of the instrument

- on several thicknesses (even over 500 mm - 0.2 in)

- on painted surfaces without any problem

- also at high temperatures up to 500 ° C

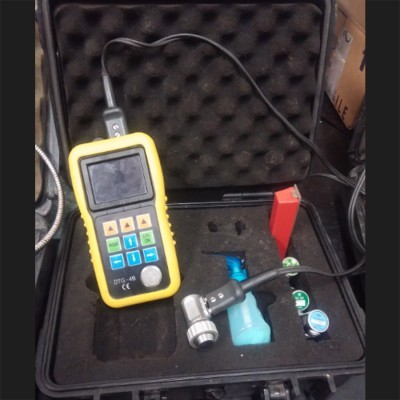

ISPECO uses thickness gauges with representation of the A-scan and B-scan signal for the continuous survey of surfaces.

Possibility of checking the thickness of the protective coating (painting), using a specific device (Fischer Dualscope).